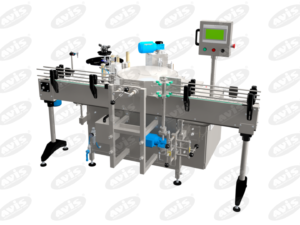

The machine is designed to form a group package of products (glass, plastic, metal, PET bottles, jars, etc.) in shrink film with its further movement to thermal tunnel for film shrinkage and formation of rigid transportation packing.

The automatic grouper allows forming packages with different number of rows – from 1 to 4, and number of bottles in the row – from 1 to 6 pieces. It works in fully automatic mode. It can be shifted to the manual mode, if necessary.

It has flexible mechanical and electronic settings for changing parameters of the group package when shifting from one format to another one. The capacity sensor controls the number of bottles. It has two drives for unwinding upper and lower film rolls.

The automatic grouper is equipped with a convenient controller to regulate the setting of a number of rows and bottles in a row, and time settings of delays by operations.

Distinctive features:

- Productivity of 6000 bottles per hour or up to 1000 packages per hour

- Possibility to form packages with different number of rows and bottles in the row

- Pulling of PET bottles is controlled with the help of the guides

- Fast settings of thermal knife temperature

- Changeover time to another bottle volume is not more than 5 minutes