The blow molding machine produces a PET bottle and feeds it on conveyors to the filling line. You only have to put the preforms into the feed hopper and press the start button. The device does everything by itself: it loads up the preforms into the machine, heat up the workpiece., blow it out and send it to the line.

Semi-automatic machines require an operator. An operator manually puts the preforms into the heating oven, take down the heated preform and put it in the blow molding machine, take down and puts together the finished PET packaging.

Productivity of the machine allows to blow from 1000 to 7000 bottles per hour, and the semi-automatic machine blows from 100 to 1200 bottles per hour. Productivity depends on the volume of blown packaging, compressor equipment and the power of the machine.

Automatic machines are more expensive. The price is several million. However, such lines pay off quickly. This option is suitable for large and medium-sized manufacturers, where the payback will not keep itself waiting long. Semi-automatic blowing is cheaper, and it is available to almost every manufacturer. Semi-automatic blowing Is suitable for manufacturer where product is filled in small batches.

The composition of the equipment for blowing

It is Individually for each site and type of packaging. Specialists of «AVIS» Company create individual solutions for specific production facilities. The composition of the equipment may differ, but the main components will be as follows:

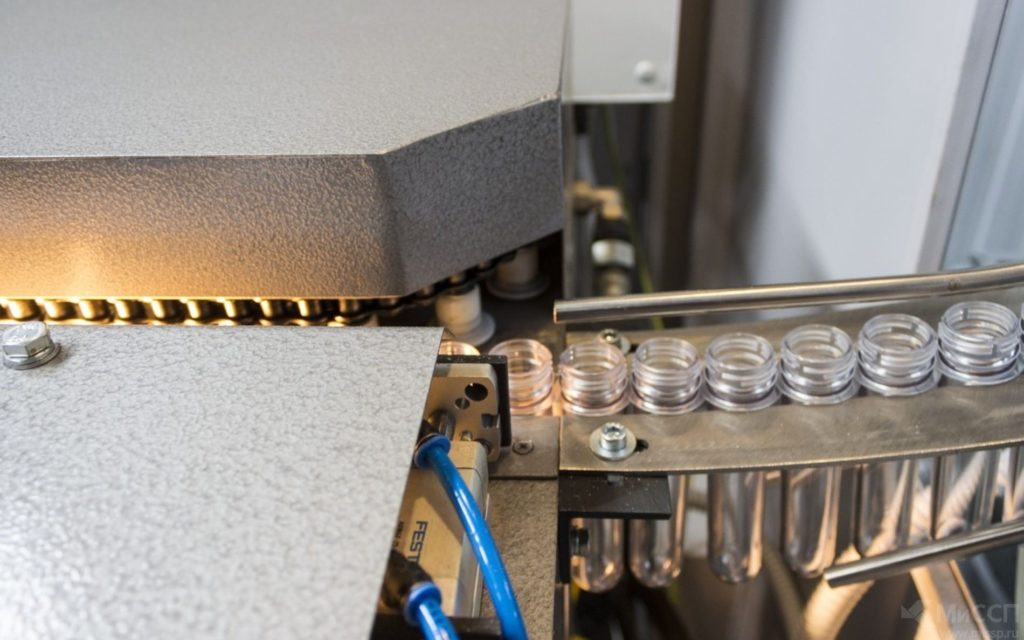

Automatic or semi-automatic PET blow molding machine

For semi-automatic blowing, two units are needed: a heating oven and a blow molding machine. In the automatic version, this is a single unit, where there is oven, blowing and cooling.

The batcher for orientation and preform feeding are set up as a separate unit.

Compressor Station or Compressor

The compressor equipment is like the heart of the whole system, it feeds the pneumatics of the machines and provides high-pressure compressed air to blow the bottles out of the preform. We will tell you more about the types of compressor equipment later.

Fluid Coolers & Compressed Air Dryers

These are secondary components, Without these there is no chance to ensure the function of compressor and blowing equipment. Dryers provide the quality of the compressed air, while liquid coolers provide the quality of the blown bottle.

Press form The final element of blow molding equipment. It is impossible to blow bottle without it. The bottle takes on the shape that was intended in the press form.