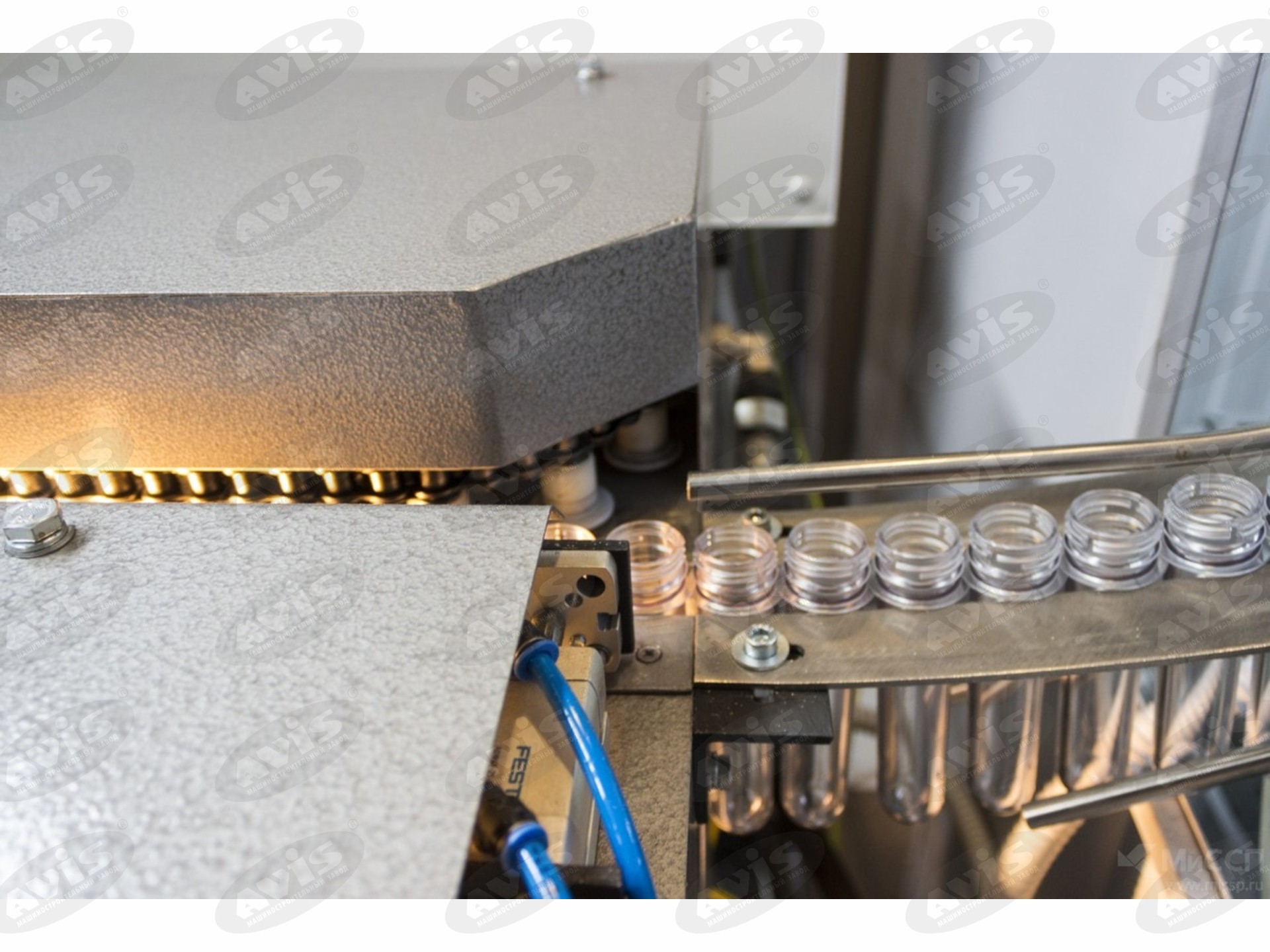

The machine is designed to produce PET bottles from preheated preforms by stretching and two-stage blowing in a three-seat mold. The machine consists of power unit, furnace for heating preforms, automatic preform loader and container with control terminal.

The volume of the bottles blown ranges from 0.25 up to 2.0 liters. The position of the units is monitored in real time. The system for the optimum temperature automatic regulation is used in the electrical cabinet. The equipment units are automatically adapted to the preset productivity parameters.

Distinctive features:

- Reliable and elaborate design of automatic PET blow molding machines provides the guaranteed work safety and comfortable operation.

- Convenient access to all components facilitates maintenance and reduces its time.

- Application of the technology of changeable movement intensity of the units decreases the load onto mechanical elements.

- Applied shuttle carriage with mechanical grips requires less operator’s attention and control, and is more reliable against mechanical impacts.

- Compressed air pressure is monitored in real time and the equipment is stopped if the compressed air pressure drops below the preset range.

- Air recuperation – the compressed air is saved due to its partial return to the system after the bottle blowing process for further use.

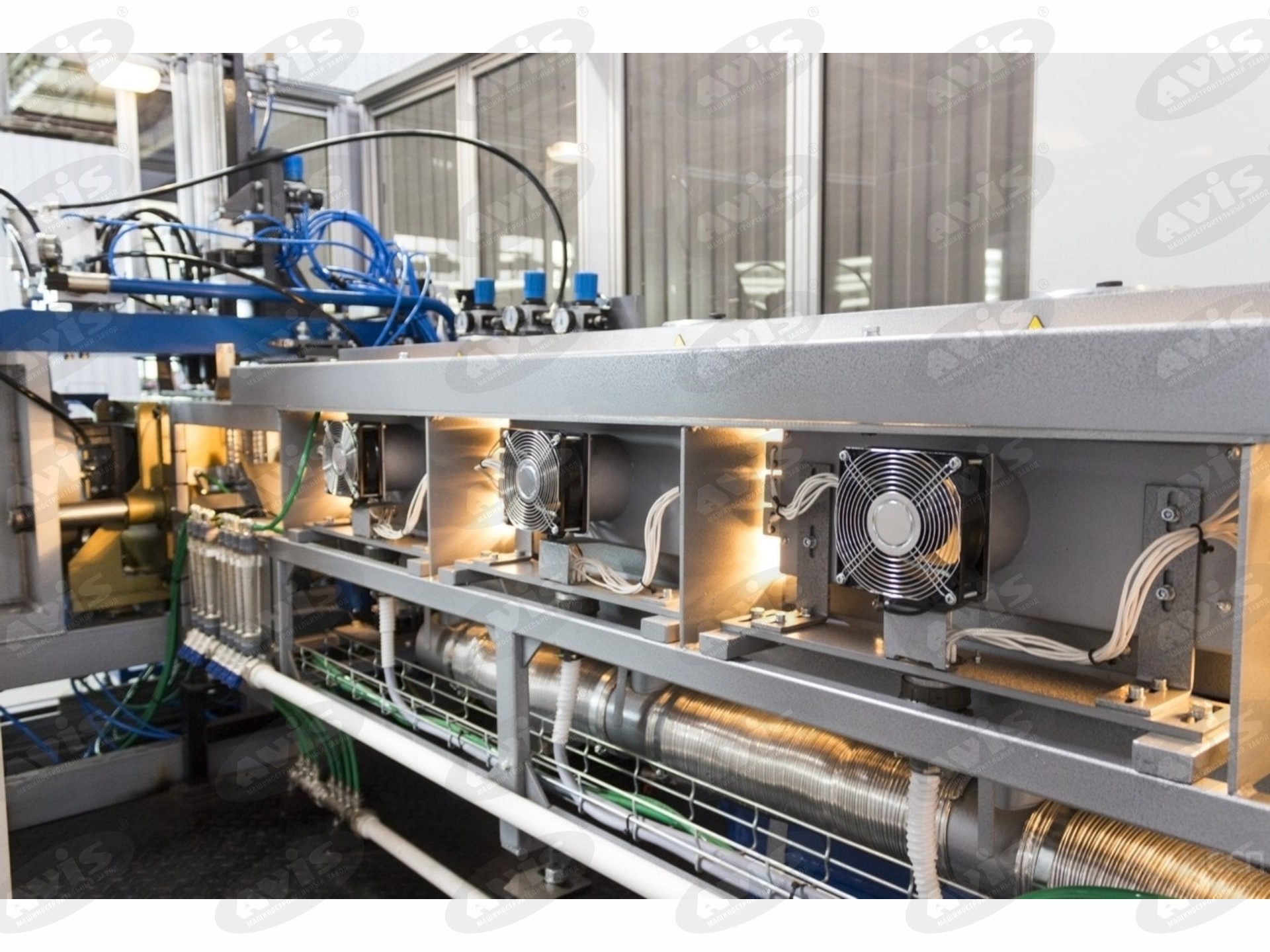

- Design of heating blocks allows regulating the horizontal positioning of the heating lamps depending on the configuration of preforms for high-quality and uniform heating and eliminates the cooling liquid feed to the reflectors of heating blocks simplifying the operation and maintenance (removal and installation of blocks).

- Applied 3-phase power system for heating lamps eliminates possible phase imbalances in the power line and decreases the total machine input power to 20%.

- Individual control of each heating zone of the furnace from the control terminal allows setting the optimum preform preheating temperature to blow high-quality PET bottles.

- Uniform heating of the preforms due to their rotation and air convection when moving through the heating furnace.

- Cooling of the preform neck when moving through the heating furnace prevents its neck deformation.