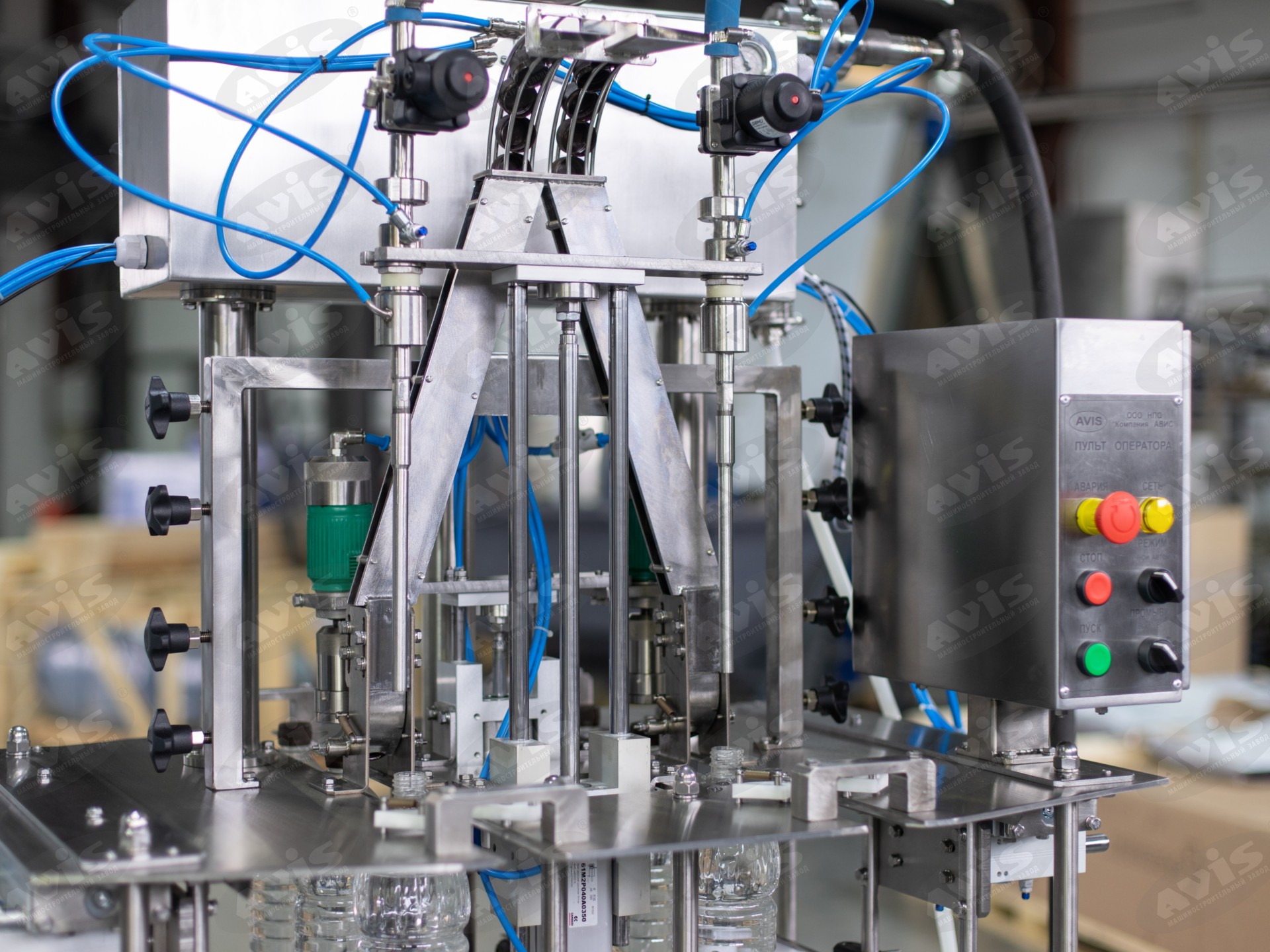

The machine is designed for filling “live” beer, kvass into plastic bottles with the volumes from 0.2 up to 3.0 liters and their capping with polyethylene screw caps. The product is dosed by isobarometric method from the bottle bottom, which allows filling strongly foaming drinks and minimizing product losses during filling.

The equipment is a monoblock – semi-automatic machine and it combines two working operations: product filling by level and capping of bottles filled. The machine is served by one operator who hangs empty PET bottles and refills the cap pipe-accumulator with caps. The pneumatic turbine with adjustable screwing force serves as the drive for capping heads. After capping, the filled and capped bottles can move along the guides to the accumulation table or conveyor, therefore, it can be integrated into the line with further automatic operations. The pneumatic turbine with adjustable screwing force serves as the drive for capping heads. After capping, the filled and capped bottles can be moved to the accumulation table or conveyor, therefore, it can be integrated into the line with further automatic operations.

Distinctive features:

- Compact size

- Two operations on one machine: filling and capping

- Works both in semi-automatic and automatic modes

- Maintenance simplicity

- Ideal solution for small manufacturing facilities or assortment batches of products