The semi-automatic machine for producing plastic bottles of the series PVM-600 MDM is designed to blow PET bottles (containers) from preforms. The machine consists of preform heating block and blowing block. The two-stage blowing method is implemented on the machine, which allows producing bottles of complex shapes. The semi-automatic machine allows blowing bottles with different neck standards by simple replacement of several elements on the blowing block and heating furnace. Infrared lamps are used as the furnace heating elements. The adjustment of temperature modes of all heating zones simultaneously and separately is possible.

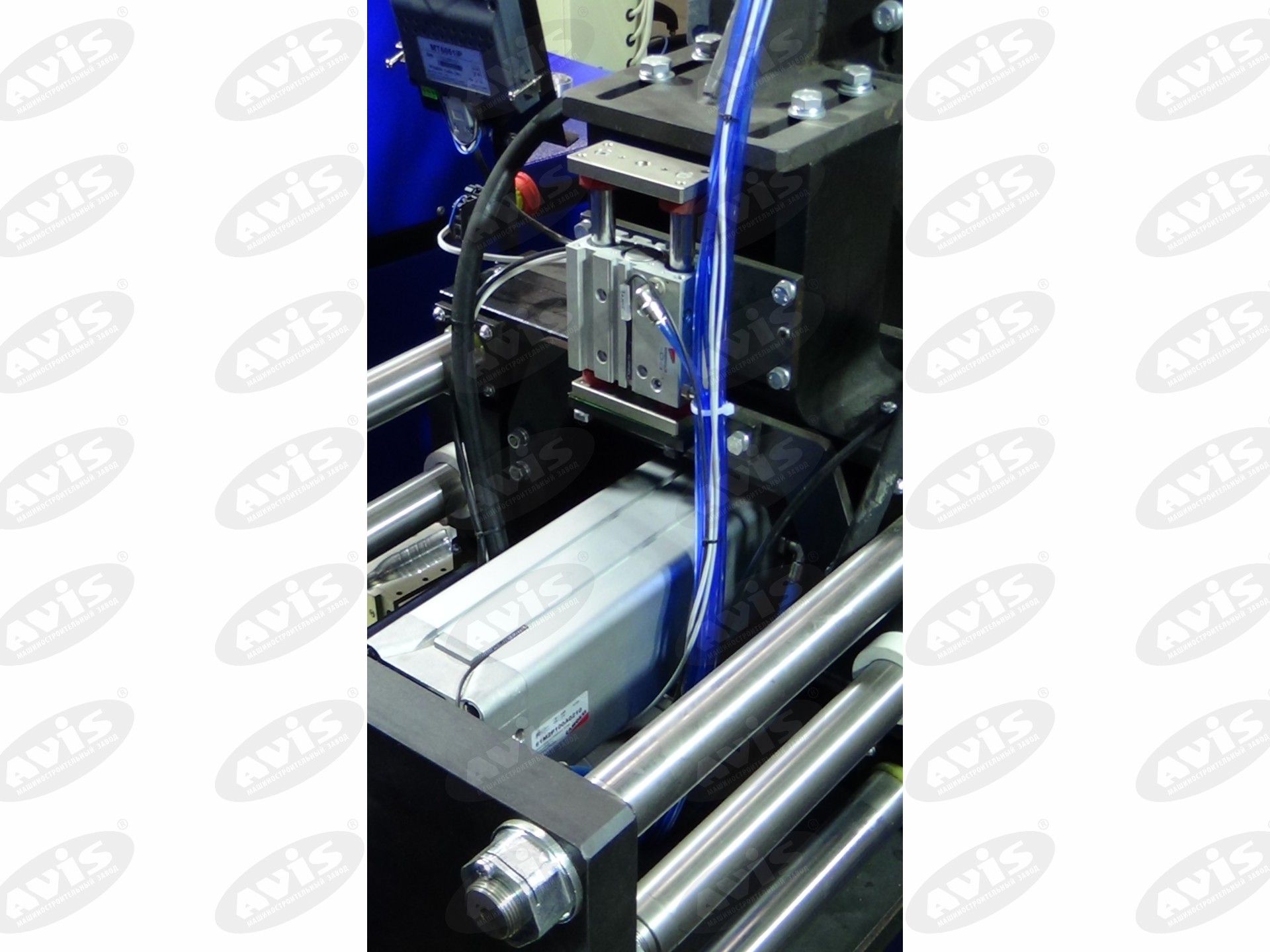

Both a single-seat and two-seat molds can be installed on the semi-automatic blow molding machine PVM-600 MDM. To work both with a single-seat and two-seat molds it is necessary to additionally order the set of changeovers . The mold replacement when shifting from one bottle shape to another one takes 15 – 20 minutes.

Distinctive features:

- availability of a booster plate, which allows minimizing the joining seam of the mold semi-matrixes

- convenient operator’s control panel in which the bottle blowing modes are set

- cycle counter for the operator’s convenience

- diagnostic mode for the serviceman’s convenience

- switching from the sensor mode to the time mode

- two modes: manual and automatic for the convenience of adjustment and operator’s work

- time required for the machine changeover to another type and size of bottles does not exceed half an hour

- original kinematic scheme.