Air conveyors TRPP are designed for horizontal transportation of empty bottles to the filling machine. The conveyor serves for connecting the blowing and bottling line elements at food, chemical and other productions.

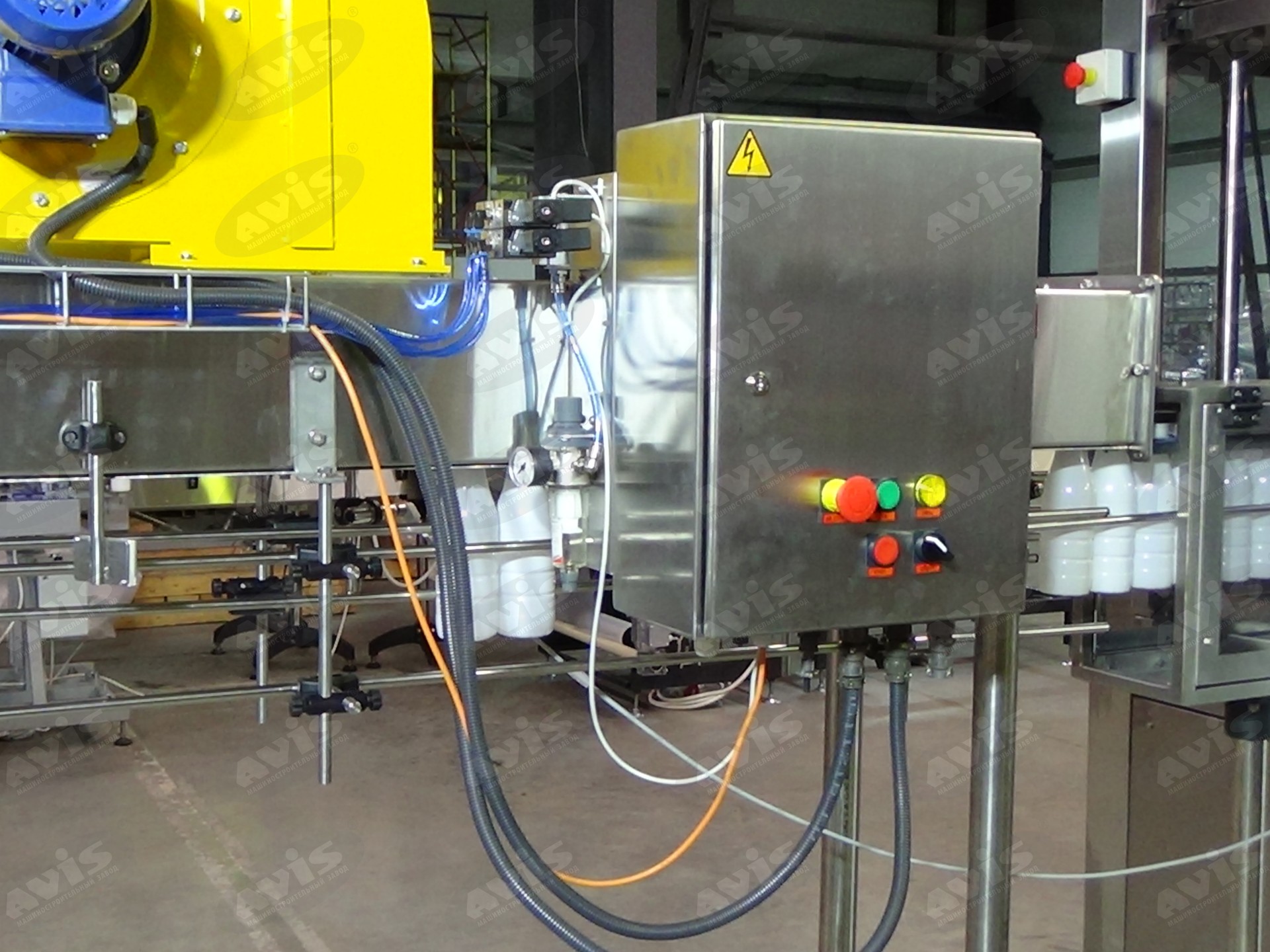

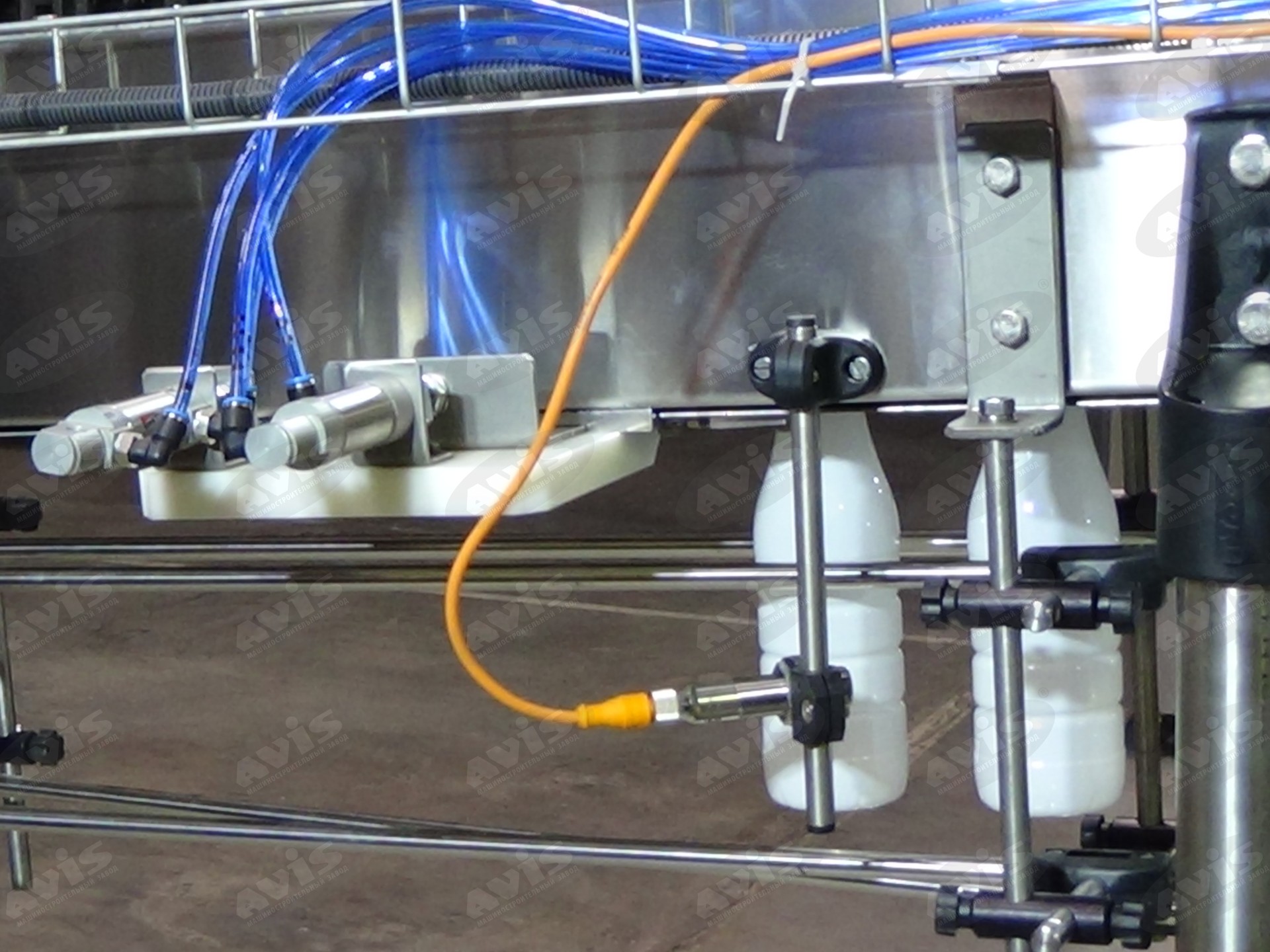

The conveyor consists of the unified section installed on the adjustable supports. The section can comprise fans equipped with filtering blocks and mechanical and electronic adjustments of the air discharge force. The fans are installed every 4 meters of the conveyor length.

The pneumatic conveyor feature is monitoring of the bottle congestion on the air conveyor. Thus, if there is bottle congestion on the conveyor or the line, the bottles will be automatically dropped through the gate. Also, due to the automatic control the bottle availability is monitored and its smooth transportation to the slat conveyor is provided through the smooth transfer device. On the filling triblocks, where the bottles are transferred by their necks, the bottle is directly transported from the conveyor to the filling machine without additional mechanical guiding units.

It is possible to manufacture conveyors of different design, height, lifting and lowering of bottles.

Distinctive features:

- Availability of the gate for automatic dropping and installation of bottles

- Conveyor design – food-grade stainless steel

- Smooth transfer device to the slat conveyor

- Production by customer’s sizes (different design, height, length, etc.)

- Fans equipped with filtering blocks and mechanical and electronic adjustments of the air discharge force