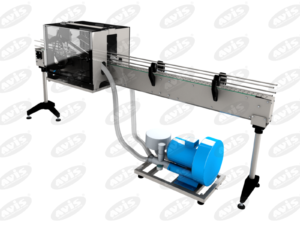

The industrial small-size water ozonation station is designed to treat water with ozone in the bottle rinsing line. The station produces ozone from oxygen.

The station operation principle is based on ozone dissolution in water by vacuum ejection method. Passing through the station, the feed water is saturated with ozone in force circulation mode. The water saturated with ozone with minimum gaseous phase reaches the station outlet. The water pressure at the station outlet equals the pressure at the inlet. The gaseous phase excess is separated in the cyclone separator, is removed through the gas separation valve and gets to the destructor where the residual ozone is converted into oxygen.

The ozone synthesis block operation is completely automated: ozone synthesis starts and stops following the vacuum relay signals when ozone emerges (vanishes) in the ozone line. The possibility of the station remote control following the external signal (dry contact) is envisaged. The pump dry running protection and protection from the pressure increase in the hydraulic circuit, if water is not consumed, are envisaged in the station design.

Distinctive features:

- Water saturation with ozone in the closed circuit

- Complete automation of the processes

- Automatic water feeding for rinsing