The triblock is intended for filling of milk and fermented dairy products into PET bottles and capping them. The milk filling triblock is a structure mounted on a single frame. It is equipped with pressure system which ensures high capacity when handling operations with fermented dairy products, such as kefir, yoghurt, fermented baked milk, etc. Container volumes vary from 0.2 to 1.4 liters. The base configuration provides high filling hygiene level, which allows extending product shelf life up to 14 days.

Air and gearboxes sterilization system ensures both pressurized and gravity filling. This allows to handle operations with milk, kefir and yoghurts with pieces of fruit on one machine ensuring maximum performance. Using nozzles designed for various products helps to avoid excessive foam and dripping of liquid upon filling.

Key features:

- Absence of “dead” zones in product feed areas

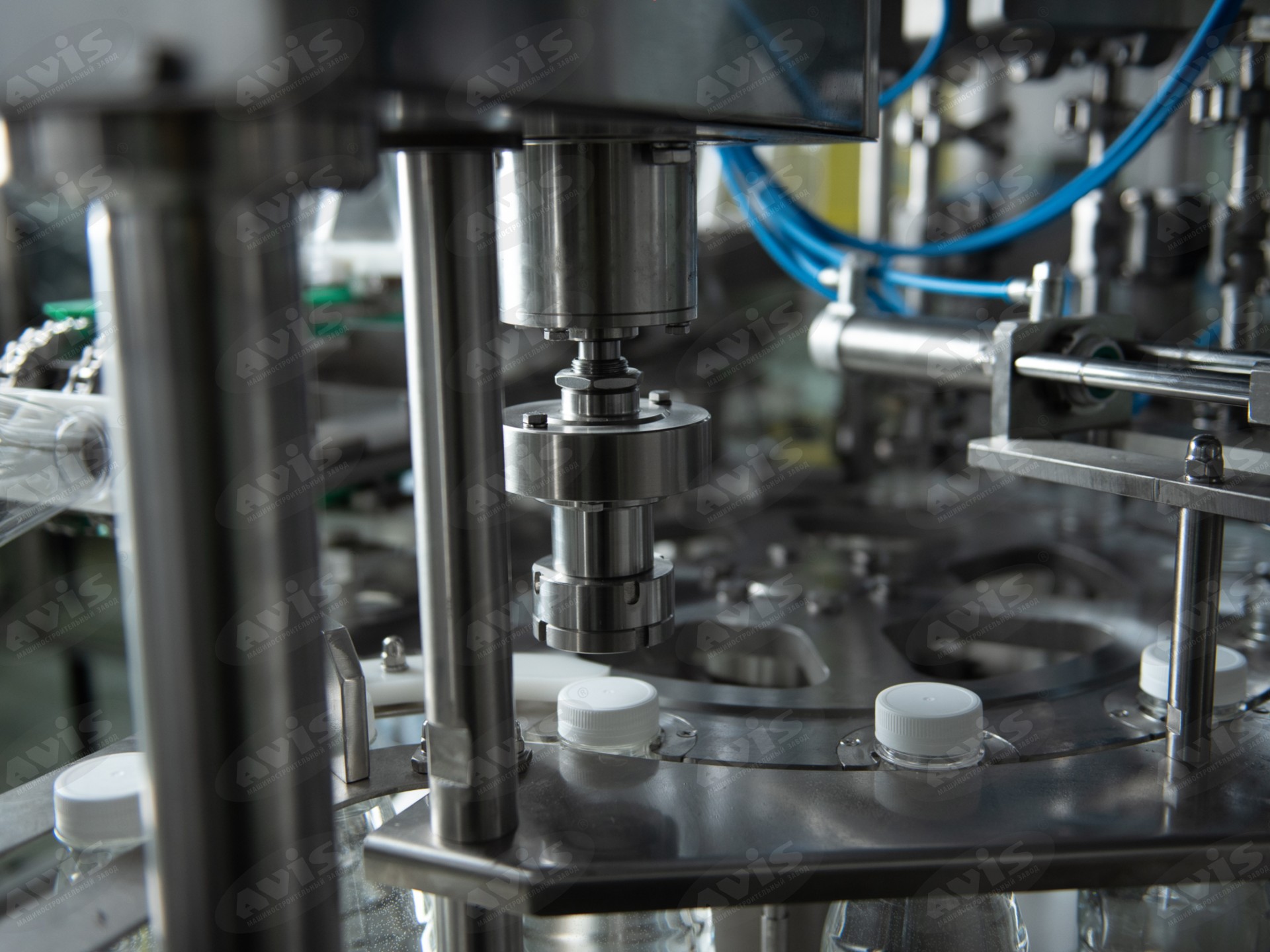

- Pick-and-Place capping system

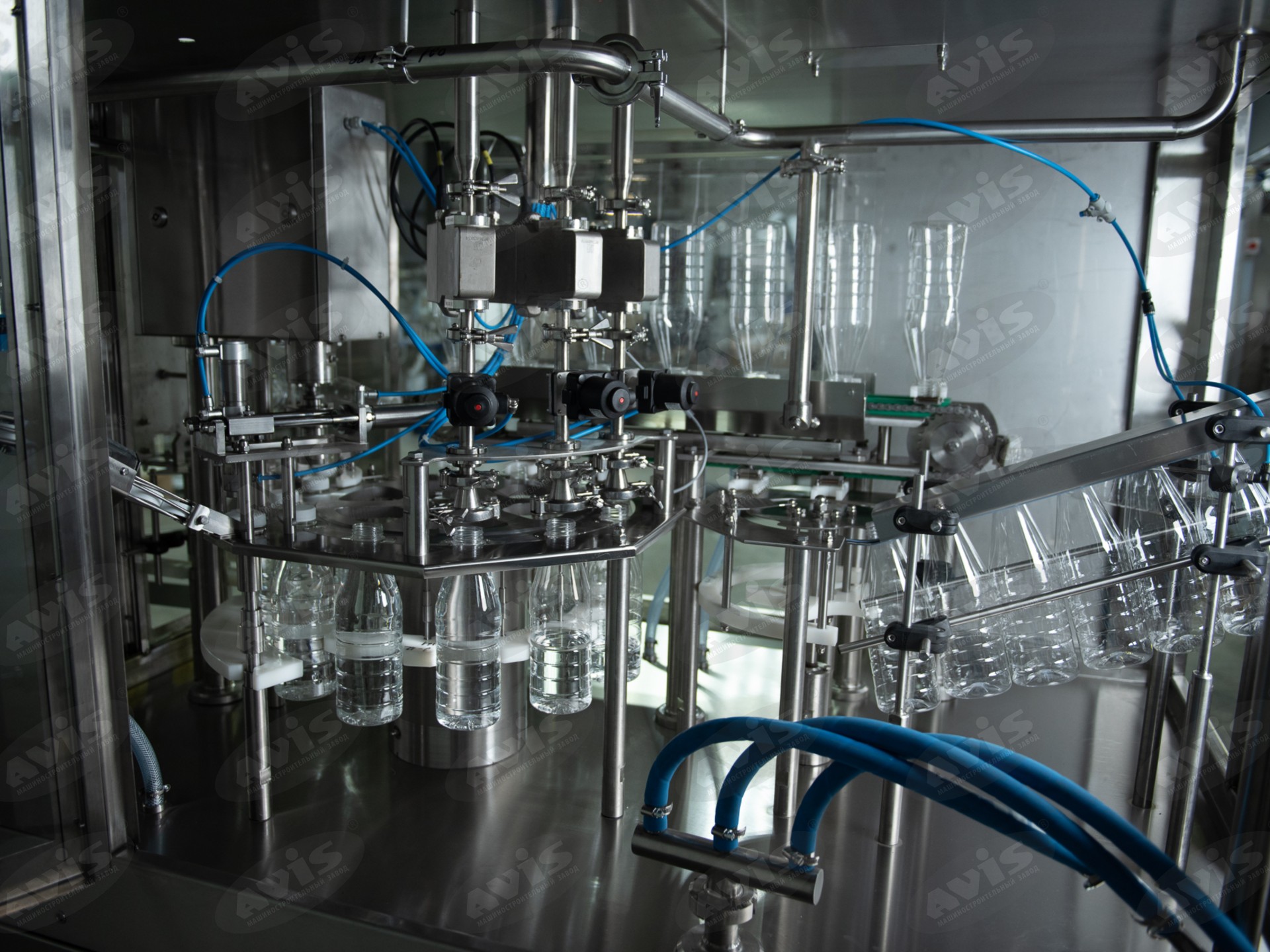

- Bottle and cap rinsing, filling and capping is carried out in an enclosed environment in accordance with all HACCP standards

- Non-contact filling – the filling head does not touch the bottle neck, so the product does not touch the bottle neck either

- Fluometric batching system – absence of “dead” zones in contrast to the piston filling method, when the joints get clogged with the product

- The feed is cut off by the aseptic diaphragm valves, capable of operating over a wide temperature range

- Inside the triblock, the bottle does not move down the conveyor belt but is suspended by the bottle neck finish, which eliminates the risk of contamination of the conveyor zone

- CIP cleaning system provides the clean-in-place circulation cleaning of product supply passages which operates independently, but can be easily integrated into company’s centralized cleaning system

- All pipework components undergo argon gas welding, and the subsequent etching and passivation processes allow to maintain the original quality of stainless steel

- All piping and product feed units can be sanitized with steam

- The equipment is made of 304 food-grade stainless steel according to the AISI standard, and the product lines are produced according to the DIN 11850 standard