General principle of operation is as follows:

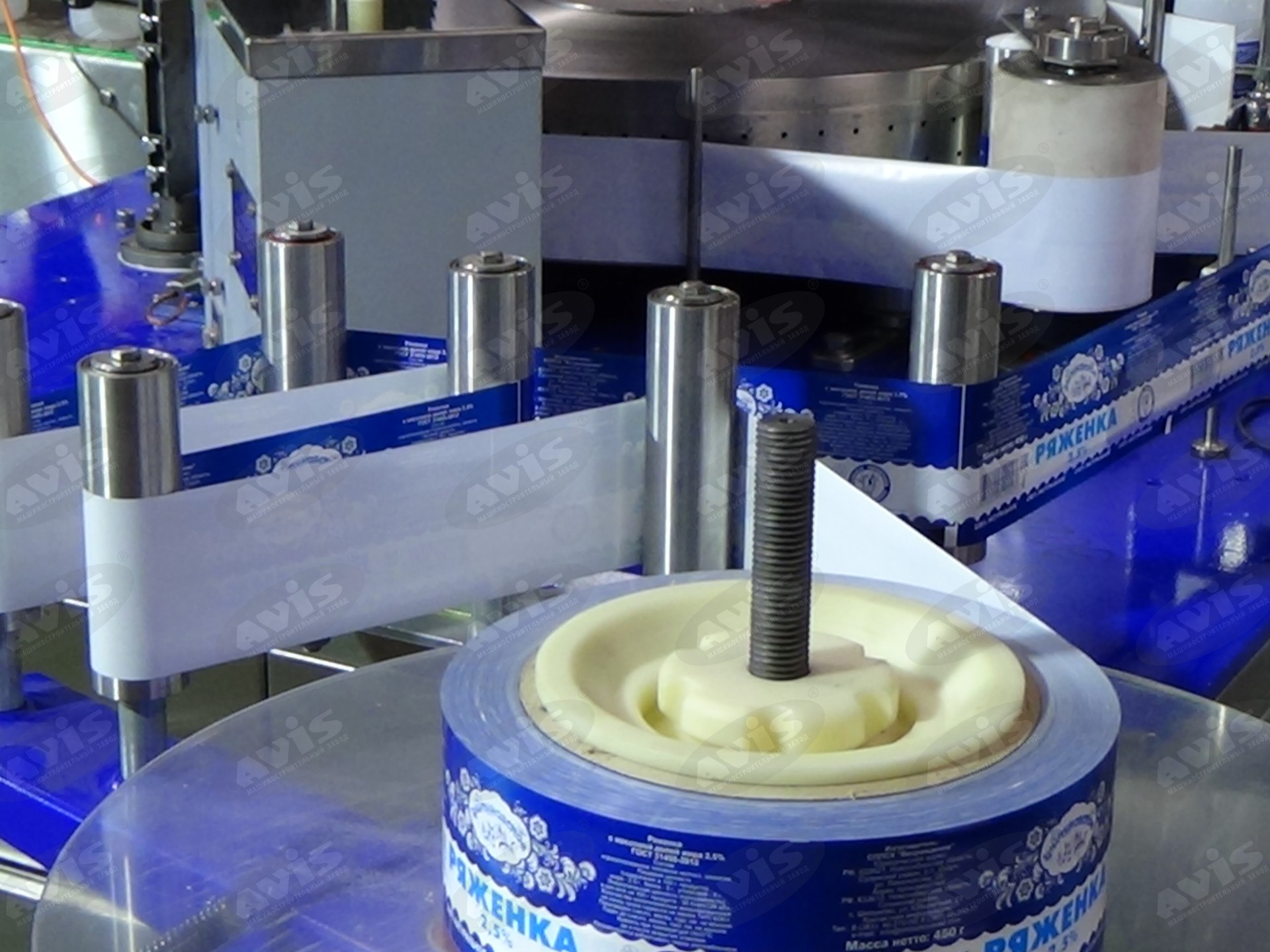

Polypropylene web is loaded into the drum and held there with the help of the perforated body and vacuum. From the paste pot the glue goes to the gluing unit and then, as a vertical stripe – onto the film. The knife cuts off the required amount of the polypropylene film. The bottle passes through the drum where the label is wound onto it and pressed.

The labeler is a well-organized mechanism, which does not practically need any interference. It can be manufactured for left- and right-side location of the equipment. The labeler is automatic, therefore, in the process of work there is no need in additional adjustments, except for the cases with changing formats or label rolls.

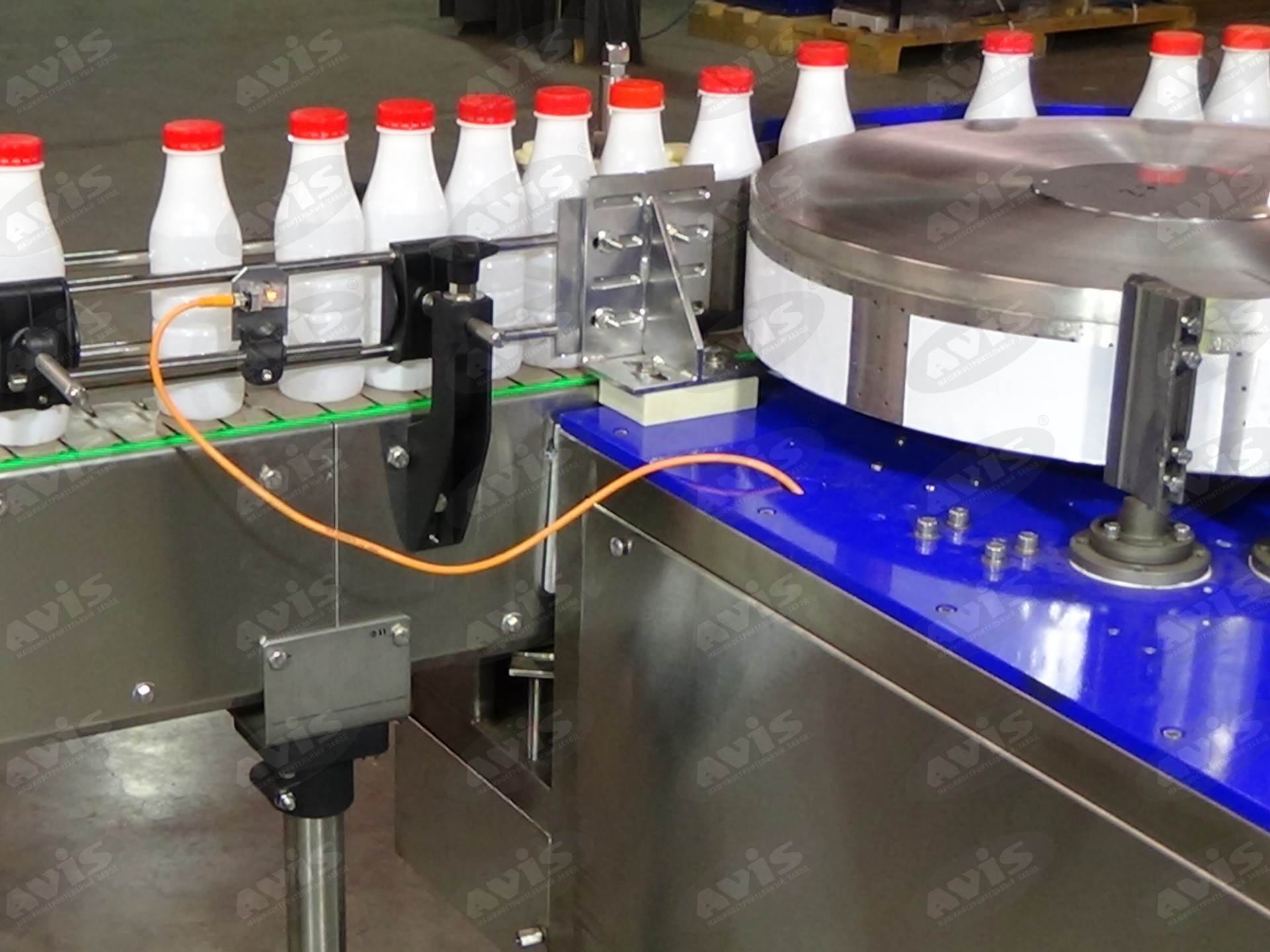

The heating temperature of the gluing unit is regulated by the production line operator. The bottles are evenly moved to the drum as the separation mechanism is envisaged.

Distinctive features:

- Label is a roll of propylene film

- Label is hold on the drum by the drum perforation and vacuum pump

- Hot glue is spread on the label as a vertical stripe

- In the process of operation the rotating gluing unit transports the hot glue from the paste pot cylinder onto the label

- Heating temperature of the gluing unit is set with the help of controller

- Rotating knife cuts the film in the middle of the gluing stripe and separates the label from the roll

- Vacuum drum presses the label to the bottle surface and, rotating the bottle along the rolling arc, sticks the label to the surface

- Bottle separation mechanism provides even transport of bottles to the drum

- Automatic labeler frame is made of stainless steel