The system is designed for automatic preparation of disinfecting solutions with specified concentration and maintaining pH of the working solution within the set up interval.

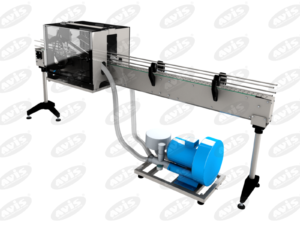

The system of preparing disinfecting solutions SPD is a stationary system, all units of which are mounted on one frame. The system main units comprise the tank, force pump and control cabinet.

The pneumatic pump fed with the compressed air, preliminary passing through the pressure-regulating filter, through the air delivery cock is installed on the tank. The pneumatic pump is connected through the pipe with the sucking device, which is drowned in the container with the concentrate. The upper level sensor, dry running sensor, drain tap and sample collection tap are embedded into the tank.

The water is fed to the tank through the pipeline. The signal on the amount of water running into the tank from the flow rate meter controls the pump operation, which doses the concentrate during the tank filling. When the tank is filled and the signal from the upper level sensor is received, the pump will switch off. To provide the automatic mode of the tank filling with water, the electromagnetic valve, which opens by timer after the tank filling, is installed after the flow rate meter. The dry running sensor is necessary to prevent the force pump operation without water. All pipelines are detachable and are connected with screwed joints.